Amazon Romulus

This project included both, incoming and branch power, site lighting, inside lighting, generators, fire alarms, and access control systems. In addition to the central warehouse, we completed electrical installations for the loading docks, kitchen, cafeteria, and offices.

On track to fulfilling its goal of same-day and next-day deliveries, Amazon has been building new fulfillment and delivery centers throughout the U.S. Several of these facilities are located in Michigan. Motor City Electric Co. and its affiliates provided electrical contracting services for Amazon’s Project Mercury, the 855,000 sq. ft. fulfillment center on Ecorse Road in Romulus.

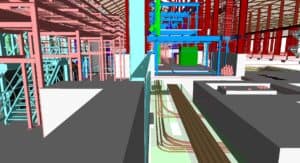

Prefabrication Process

The MCE Prefabrication department played a significant role in this project, assembling lighting fixture feeds, disconnect racks, and cord drops in the shop. Prefabricated assemblies then arrive at the job site for installation. Roughly 14 football fields in length, Amazon Romulus opened for business in July 2018 and employed 1,500 workers. The fulfillment centers are so automated and filled with conveyors and robots that Amazon bought the mobile robotic fulfillment systems company! Amazon purchased Kiva Systems LLC in 2012 and renamed it Amazon Robotics LLC.

In the Amazon Fulfillment Centers, workers do not need to go to the shelves. The shelves come to them. Workers first enter products that arrive at the fulfillment center into the system. The items arrive in yellow plastic tubs. A worker in the stowing station pulls a package from a tub, scans it into the system, and pops it into an empty slot on tall, yellow portable storage units (pods). When the pod has no more open spaces, the employee hits a button, and the pod whirs away into the depths of the warehouse while others slide in behind it. This process takes just a second or two. As soon as an item enters a storage pod, it becomes available to the customer. Workers at different stations process customer orders and call up items for packaging.

Delivery System Database

When an order comes into the Amazon database system, the software locates the closest automated guide vehicle (bot) to the item and directs it to retrieve it. The short, orange bots navigate the warehouse by following a series of computerized barcode stickers on the floor. Each drive unit has a sensor that prevents it from colliding with others. When the bot reaches the target location, it slides underneath the pod and lifts it off the ground through a corkscrew action. The bot then carries the pod to the specified human operator to pick the items. Imagine a more significant and square Rumba vacuum with a circle on top that can lift and cart off the shelving units.

The bots are battery-powered and need to charge every hour for five minutes. Smaller bots measure approximately 2 feet by 2.5 feet by 1 foot high and can lift 1,000 pounds. The large robots can carry pallets and loads as heavy as 3,000 pounds. The maximum velocity of a bot is 1.3 meters per second or roughly 256 feet per minute. The automated system is far more efficient and accurate than traditional workers traveling around the warehouse locating and picking items. The rest of the facility is a massive network of conveyor lines. Amazon says if you laid out all the conveyers at the Romulus facility end-to-end, they would stretch more than 10 miles.